For many years, SCAM has been specializing in the design and manufacture of on-shore and marine plants for the production of fresh water from sea water. Thermal processes principally used for the separation of salts were: submerged tube plants, multi-stage flash, thermo-compression, heat recovery.

The advent of new technologies employing semi-permeable membranes found us ready to face the required studies.

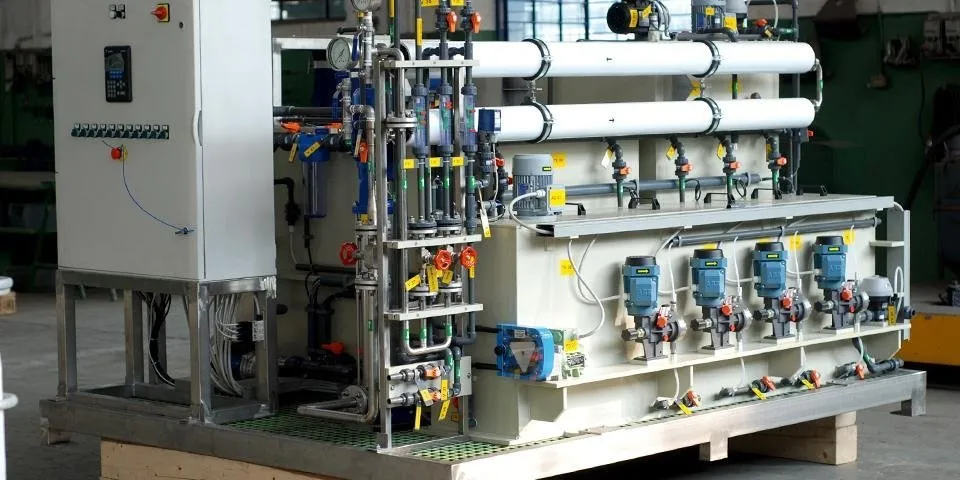

The results of these studies have enabled us, recently, to realize reverse osmosis plants (reverse osmosis system).

Experience, the technical co-operation with Engineering Companies and Test Institutes – that have been inspecting operating plants for more than ten years – allowed us to develop a line of package type “Reverse Osmosis Sea Water Desalting Plants”, with a capacity ranging from 1 to 2,000 T/day. For higher outputs, SCAM-RO plants are designed every time according to our Customers’ requirements.

Reverse Osmosis Uses

Pure and ultra-pure water produced by means of the Reverse Osmosis system is specifically recommended for the following uses:

Materials

SCAM-RO units are tested at our Workshop before the delivery.

They can be supplied for on-shore use with tubes and tanks in plastic material or fibreglass either for marine applications with materials complying with the rules of Test Agencies such as R.I.Na., LL’R, B.V., etc.

Energy Recovery

Since the brine discharge occurs at high pressure, SCAM introduced an energy recovery system that provides a substantial reduction in plant running costs.

Membranes

The choice of membranes, the complexity of pre-treatment and materials are based on individual applications, our experience and by several test results we achieved. The point of departure for every reverse osmosis plant is the study of the characteristics of the salted or brackish water to be treated. SCAM can supply units with a wide range of membranes for specific cases. Materials used in the production of membranes have the following advantages:

Cellulose Fibre

- Greater resistance to the effects of free chlorine up to 1 mg/lt. for long periods, from 10 to 20 mg/lt for short periods;

- Greater productivity in relation to the membrane surface;

- Lower micro-porosity impedance.

Polyamide Fibres

- Wider pH tolerance;

- Greater resistance to biological attack;

-

Greater salt rejection capacity.